Contamination of high-touch surfaces is responsible for the transmission of pathogens in various settings. Its impact is most severe in school and health care facilities and is one reason why health care-associated infections (HAIs) continue to be such a serious problem.

Although the number of HAIs has been steadily decreasing in the United States, “on any given day, about one in 31 hospital patients has at least one health care-associated infection,” according to data from the U.S. Centers for Disease Control and Prevention.

In school environments, contaminated surfaces not only spread disease within classrooms but also can spread infections, such as influenza, within a community.

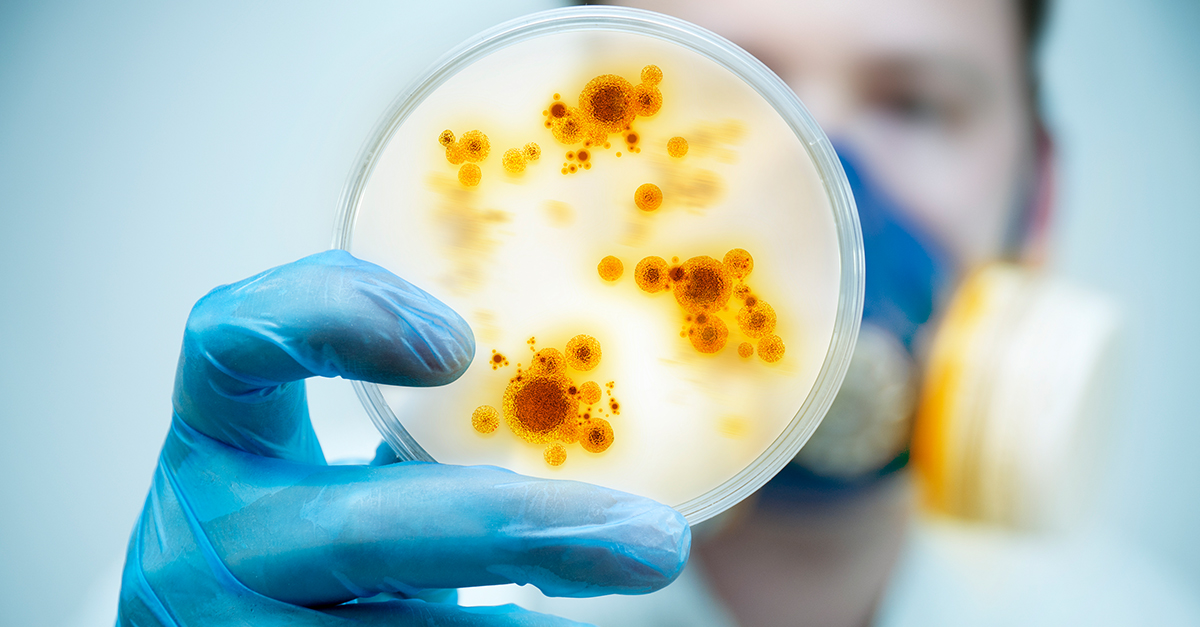

The professional cleaning industry plays a crucial role in stopping the spread of infection, but before cleaning staff can eliminate pathogens, they must first find them. In the past, laboratory technicians would swab surfaces and use a petri dish culture to confirm the presence of pathogens. The findings would not be available for two to four days, giving the germs opportunity to sicken more people.

Technological advances are providing quicker methods to locate pathogens, enabling the professional cleaning industry to better meet its goal of protecting human health. While these technologies have drawbacks, they do show promise.

Prove Contamination With Paper Stickers

In May 2019, a report in the Journal of the American Society for Microbiology found that paper stickers can be an effective tool to determine if contamination exists on surfaces. For up to seven days, researchers placed stickers on multiple high-touch surfaces in food service locations. After analyzing the stickers, the researchers found they revealed a considerable buildup of contamination on these surfaces.

Paper stickers are an inexpensive, simple, and effective method to locate contamination. However, the analyzation process takes valuable time, and the stickers only pick up pathogens on the area tested, not the surrounding area.

ATP Marks the Spot

Although adenosine triphosphate (ATP) has been in use since the 1930s, it was first introduced to the cleaning industry about a decade ago. ATP monitoring systems detect living cells on a surface. Users simply swab a surface then place the swab inside the ATP unit. Results are usually available in about 20 seconds.

While ATP does not reveal which specific pathogens are on a surface, it serves as a red flag that they may be present. Cleaning professionals use ATP to test a surface before cleaning and again after cleaning to determine cleaning effectiveness. However, like paper stickers, ATP only detects pathogens on the specific areas tested.

Imaging Paints a Wide Picture

The health care industry, one of the first industries to use imaging technology, found it useful to find the growth of cancer and other abnormalities in the human body. In the professional cleaning industry, workers use imaging technologies in schools, food service facilities, and health care settings to take pictures of a wide area. These pictures indicate if pathogens are present based on the color, intensity, and concentration of images shown.

Taking Responsibility for Infection Control

While the obvious reason for using technologies like the ones mentioned above is to quickly find and remove pathogens, cleaning professionals should be aware that there is something much bigger at play here.

Many germs are developing into superbugs that spread diseases immune to the medications used to treat them. Pharmaceutical companies have set a limited amount of time and money in developing new antimicrobials. This puts greater responsibility on the cleaning industry’s shoulders to find and proactively eradicate harmful pathogens. With these technologies and the implementation of effective cleaning methods, we will be up to the challenge.