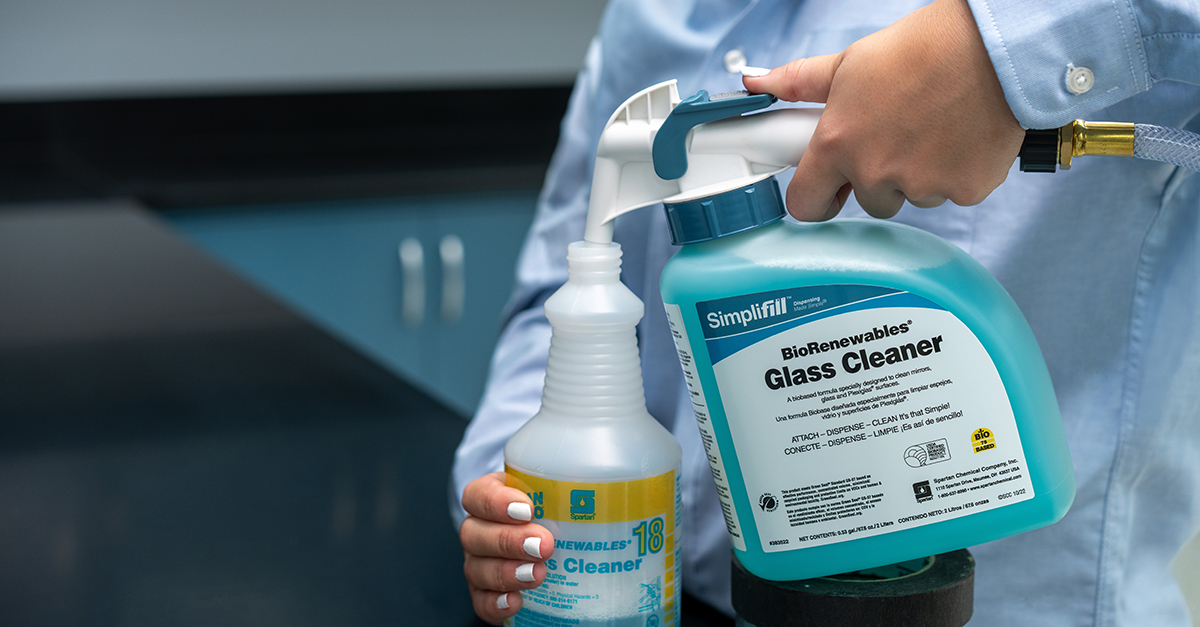

If you’re in the cleaning industry and tired of the guesswork that comes with chemical dilution, the Simplifill® dispensing system by Spartan is a game-changer. This portable, easy-to-use system delivers precise chemical dilutions every time—no wall mounts, minimal training required, and no more over- or under-dosing. It simplifies operations while ensuring optimal cleaning results.

HERE’S HOW IT WORKS:

- Attach your water source to the quick-connect.

- Dispense with the press of a trigger.

- Clean with confidence using the right dilution every time.

Simplifill® offers a plug-and-play solution that eliminates contact with concentrated chemicals. Featuring a wide range of Spartan’s trusted products, it allows cleaning professionals to tackle a variety of surfaces efficiently and safely.

An independent time study conducted by ISSA Consulting validates that the Simplifill® system brings measurable operational improvements and considerable cost savings to multi-site commercial cleaning operations.

THE DETAILS

The product: Simplifill® from Spartan Chemical

The claim: This portable dilution system delivers significant operational improvements and cost savings for multi-site commercial cleaning operations. The study specifically demonstrates

how the system reduces inefficiencies, such as travel time to and from janitorial closets and maintenance efforts, resulting in increased productivity and labor savings.

The validators: ISSA Consulting and the ISSA Cleaning Times validating organizations

The purpose: To examine the operational impact and cost savings of implementing Simplifill from Spartan Chemical in multi-site commercial cleaning operations, providing evidence that

adopting the system can drive measurable improvements in terms of labor costs and operational efficiency

REAL-WORLD SCENARIO 1

Multi-building office park:

- Total additional travel time to and from janitorial closets per cleaning cycle: 24.56 minutes

- Square footage cleaned: 26,780 sq ft

- Primary inefficiency: Staff repeatedly returning to central locations for mop bucket refills

In practical terms, this represents nearly 25 minutes of paid labor time per cleaning cycle that generates zero revenue. For a facility cleaned daily at a $15/hour labor cost, this results in $6.14 in lost productivity per day, or $1,580 annually for this single location.

REAL-WORLD SCENARIO 2

Mixed-use corporate facility:

- Total additional travel time to and from janitorial closets: 53.34 minutes per cleaning cycle

- Despite having three strategically placed dilution stations

- Annual cost impact: $3,453 in lost productivity (assuming daily cleaning at $15/hour)

THE SOLUTION: PORTABLE PRECISION

Simplifill® addresses inefficiencies by bringing the dilution system to the work, rather than bringing the work to the dilution system. Cleaning technicians can maintain their productive rhythm by refilling mop buckets and spray bottles at the point of use without breaking concentration or losing momentum. Furthermore, the system’s portability enables dynamic scheduling optimization. Instead of planning routes around fixed dilution points, supervisors can assign work based purely on cleaning priorities and traffic patterns. This flexibility becomes particularly valuable in facilities with varying occupancy schedules, construction zones, or seasonal space reconfigurations where traditional dilution stations may become temporarily inaccessible.

BURDEN ELIMINATION

Traditional dilution systems, like VersaFill® 3, often require regular upkeep to ensure proper functioning and accuracy. This includes periodic, manual, dilution accuracy checks. While this procedure is manageable and well-suited for fixed-site operations, it can consume valuable time and resources over the long term.

Simplifill® eliminates this ongoing maintenance burden. With its integrated precision dilution technology, there’s no need for manual verification. The result is not only a reduction in downtime and technician oversight but also greater consistency in cleaning outcomes.

Dilution testing verification comparison:

- VersaFill® 3 testing time: 2.23 minutes per test

- Typical testing frequency: Weekly

- Annual maintenance time per location: 116 minutes

- Simplifill® maintenance time: 0 minutes

FINANCIAL IMPACT ANALYSIS

Labor cost savings example (Medium-sized operation with 10 locations):

- Reduced travel time to and from janitorial closets

a. Average savings per location: 38.95 minutes per cleaning cycle

b. Daily cleaning frequency: 5 days/week

c. Annual savings: 1,013.7 hours

d. Annual value at $15/hour: $15,205 - Maintenance elimination

a. Dilution accuracy testing time saved: 131.44 minutes annually per location

b.10 locations × 21.9 hours × $15/hour

c. Annual savings: $3,285

Total Annual Savings: $18,490

ADDITIONAL VALUE DELIVERED

While both traditional wall-mount dispensers and Simplifill® offer value depending on the environment, Simplifill® delivers a unique blend of operational flexibility, ease of use, and labor savings that extend beyond just time on task.

- Quality consistency: Precise dilution prevents inaccuracy and ensures consistent outcomes.

- Employee satisfaction: Less travel means less fatigue and better morale.

- Competitive advantage: Improved efficiency allows for more competitive bids.

- Operational agility: Simplifill® adapts to dynamic work environments with ease.

TRAINING REQUIREMENTS

Simplifill® is designed for ease of use, drastically reducing the training time required to onboard new staff. On average, training time is reduced from 45 minutes to just 15 minutes compared

to traditional systems—a 67% reduction. This enables faster deployment, especially in high-turnover environments.

RECOMMENDATIONS

For Building Service Contractors (BSCs):

- Best for multi-site operations with dispersed facilities

- Ideal for locations with no custodial closet or limited utility access

- Reduces high cost of training in high turnover environments

For In-House Facility Managers:

- Suited for buildings with decentralized cleaning needs

- Enables schedule and route optimization

THE RESULTS

The ISSA study confirmed what many cleaning professionals already suspect—nonvalue-added activities, like unnecessary travel to and from janitorial closets and manual testing, undermine

productivity. Simplifill® addresses these pain points by delivering a more streamlined and efficient workflow.

Key findings:

- Up to 53 minutes of travel time eliminated per cleaning cycle

- 100% of dilution testing procedures eliminated

- Estimated annual savings: $12,000 to $18,000 for medium-sized operations

For an industry that operates on thin margins, solutions like Simplifill® that deliver measurable improvements without compromising quality are invaluable. By converting nonproductive

time into high-impact cleaning time, Simplifill® provides a true operational edge.

*This case study is based on independent time study data conducted by ISSA Consulting in October 2024. Results may vary based on facility characteristics, cleaning frequencies, and local labor costs.