In recent years, broken links in the supply chain have increased friction across industries. In nearly every sector, we have grown accustomed to waiting longer, paying more, and seeking alternative solutions when the first choice is not available.

How should manufacturers respond to these market pressures? At Americo Manufacturing Company, quality and innovation are central to our strategy and operations. In the current environment, that means not only developing superb products, but also adding value from production to delivery.

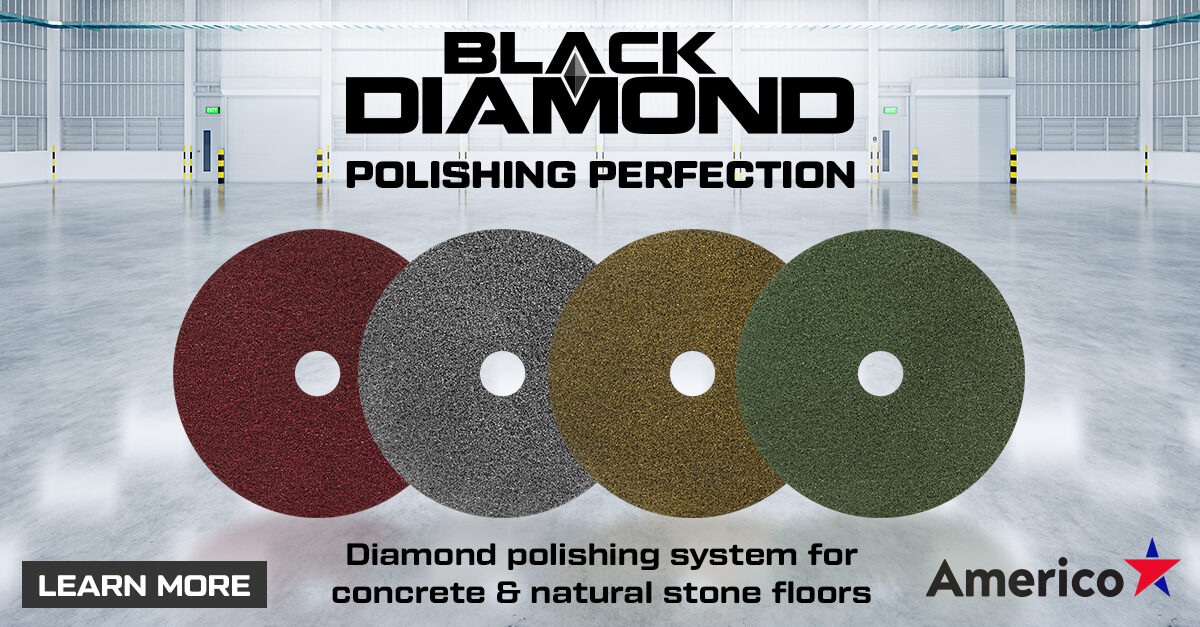

We achieved this with the newest addition to our product line, the Black Diamond Cleaning and Polishing System. This four-pad system is specially designed to restore, clean, and polish smooth concrete and natural stone floors. Made from a base web of 100% recycled PET fiber, Black Diamond incorporates our Integrated Matrix Technology™, the proprietary binding system which generates maximum adhesion and concentrates diamonds at the strongest points of the web matrix. These innovative pads are wholly produced at Americo facilities, giving our customers a single-source advantage.

“I firmly believe that our internal management of the entire production process for Black Diamond gives us the ability to maintain a stable guarantee for a high-quality product,” says Quality & Safety Manager Zachary Ponder. “Because Americo oversees every aspect of both the base web creation as well as the spray application with meticulous attention to detail, we can confidently deliver a superior end-product that not only exceeds customer expectations but also upholds our reputation for unwavering excellence in our service.”

This focused consistency pays dividends in performance and durability. Black Diamond outperforms leading competitors by 25% in gloss meter readings. Following use, even well-worn floors show an initial gloss increase of up to 300%. Additionally, Black Diamond is up to 15% more durable than competitors with an expected pad life of +/-500,000 SF when used for daily cleaning procedures.

Single-source manufacturing also eliminates costs and delays associated with freight in the production process. This allows us to pass significant savings on to our customers, with the added benefit of short lead times.

To get the maximum benefit from this customizable floor care system, we recommend assessing the starting condition of the floor and determining the desired end result.

- Black Diamond 400 removes scratches and stains from worn concrete and natural stone floors with course-grit restorative action.

- Black Diamond 800 removes light imperfections and deep cleans floors to prepare them for polishing.

- Black Diamond 1500 brings out the floor’s natural luster with initial polishing. This step produces a matte gloss level which can be maintained with continued use.

- Black Diamond 3000 is the fine-grit daily maintenance step and delivers polishing perfection with a brilliant, high luster appearance.

Get started today! Contact Americo to learn more or to schedule a local demo.

A subsidiary of Clean Solutions Group headquartered in Acworth, Georgia, Americo Manufacturing Company supplies floor pads, cleaning accessories, and matting products for the Jan/San industry. Combining rigorous quality with sustainable practices and proven technologies, Americo is an industry leader envisioning A Cleaner Way Forward™.