Slips, trips, and falls rank No. 3 on the National Safety Council’s list of workplace injury events that result in lost days of work with over 300,000 cases in 2018. Liberty Mutual’s 2018 Safety Workplace Index ranks the most disabling U.S. workplace injuries and reports that trips, slips, and falls account for 33% with an estimated cost of $19.4 billion.

While facilities management professionals are increasingly challenged with limited resources and restricted budgets, the health and safety of building occupants and visitors are top priorities. A properly designed entrance system supports maintenance teams by removing moisture and debris from the bottom of footwear to reduce the risk of slips and falls.

Recognize an Ineffective Entrance System

If you need to distribute multiple 4-feet by 8-feet mats throughout the lobby when it snows or rains, not only is your entrance system not performing as it should, the end-to-end mats can also shift to become a tripping hazard. The need to regularly post wet floor signs near the entrance and throughout the lobby may also be a sign of an ineffective entrance.

Examine your facility for moisture, dirt clumps, or muddy footprints being tracked onto surfaces beyond the entrance and look for scratches, scuffs, and damage on interior flooring surfaces. Any of these conditions may warrant an entrance audit.

Audit Your Entrances

Periodically audit your entrances for effectiveness and safety. Check for tripping hazards such as uneven surfaces or transitions from one area to another.

Make sure that any loose-laid matting lays flat, is free from buckling or curled edges, and stays securely in place. Wear patterns and discoloration often signal that your matting is reaching the end of its useful life. When vinyl backing or rubber molding is showing through the top surface, the mat is no longer adequately removing moisture.

Look for gaps in your entrance system that expose hard-surface flooring. These gaps may have been purposeful or caused by mats shifting as people walk across them. In either case, the gaps are posing safety hazards as well as allowing exposed areas to become damaged.

Inspect deep-recessed foot grilles, which are often installed in entryways for scraping debris off shoes in high-traffic environments, such as in schools, hospitals, and Class A buildings. Replace any panels that have weak or broken joints or rails.

Foot grilles that become slippery when wet are ineffective but are still found in many buildings. Facilities personnel typically place mats over the slippery surfaces for safety, but then the grilles are no longer performing their scraping function. The best solution is to replace them with a proven nonslip foot grille product.

Metal grilles that rattle as you walk across them can be annoying but are not necessarily ineffective. Check for warped panels, dents, and worn-out fiber inserts. Replace damaged sections or entire panels with the identical model or replace the entire grille portion with another modern scraping product.

Improve Matting Performance

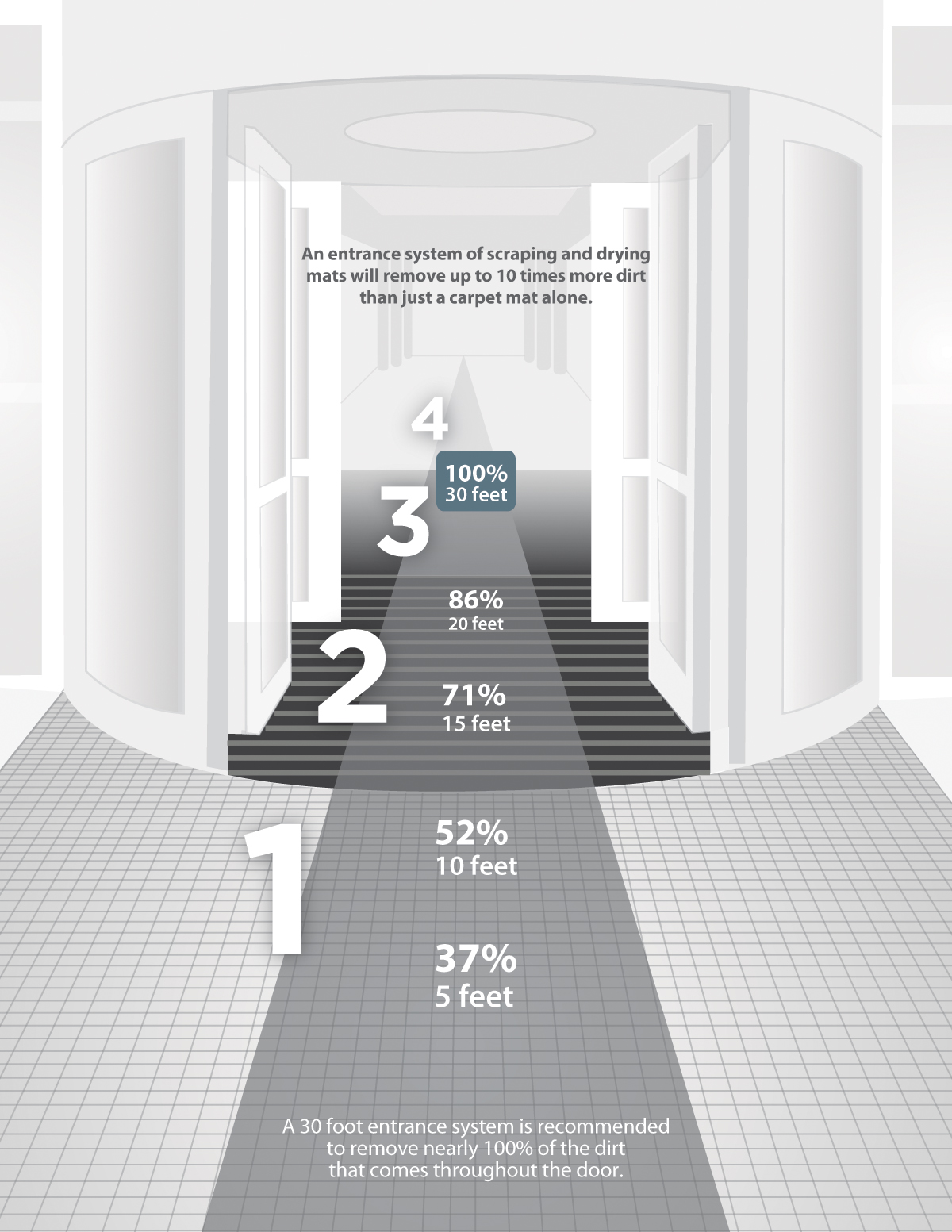

If you need to replace your entrance system or improve its performance, keep in mind that the most effective systems are a minimum of 20 to 30 feet in length and are comprised of multiple materials designed for scraping and absorbing soil.

Outside the entrance (if there is an overhang) or beginning in the vestibule, choose an aggressive scraping product that is as maintenance-free as possible. A deep-recessed foot grille provides the best results in both areas, though it is typically planned in the original construction. Without a deep well at the exterior, opt for an easy-to-clean, weather-resistant scraping mat.

A dual-track foot grille with alternating metal scraping bars and coarse fiber strips is preferred for removing dirt and moisture in vestibules. If your facility vestibule cannot accommodate deep-recessed grilles, shallow-recessed and surface-mounted alternatives made of metal or vinyl will do the job but will require more frequent maintenance.

Make sure interior matting extends across all doorways and fully covers traffic patterns inside the lobby without leaving any hard surfaces exposed. Custom shapes and sizes are often the best solution for multidirectional traffic patterns. Polypropylene matting is manufactured in a variety of styles such as berber nops and looped ribs, comes in different pile weights, and is available in many colors. It performs double duty by scraping small particles and wicking away moisture. Choose 100% solution-dyed, UV-stabilized polypropylene to ensure the color doesn’t wash out or fade, avoid molded rubber matting with a thin fiber covering, and opt for a heavy-duty pile weight for a longer-lasting system. Matting with soft nylon pile and visible or invisible scraping fibers is produced in a variety of colors, formats, and pile weights, and is an attractive alternative in lobbies with lower foot traffic.

Improving your entrance system’s effectiveness is not only beneficial for the safety of building occupants and visitors, it also will improve indoor air quality, extend the life of flooring, and reduce interior maintenance.