For decades, cleaning technicians employed the same practices to clean and maintain floors since there had been no dramatic changes in flooring types. While there were occasional updates to flooring material, such as new carpet fibers, for the most part, the processes employed in the floor care trade adapted easily to any slight flooring update—until the introduction of luxury vinyl tile (LVT).

LVT has undergone several changes since it was introduced in the 1970s to become what we know it as today. It has proved to be a popular flooring choice in commercial environments due to its noise-canceling properties and its low maintenance costs. According to statistics for the 2019 sales year reported in Floor Covering Weekly, the amount of LVT flooring sold has nearly quadrupled in the past six years. If you have not seen this flooring type in your facility, it is a good bet you will see it soon.

What makes LVT different?

LVT flooring has a vinyl base layer covered by a photograph of whatever the manufacturer wants the floor to look like, which is typically a wood-grain pattern. The photograph is covered by a protective layer of plastic, which is then covered by a urethane layer with additives to give the coating its durability and to act as a wear layer

The depth of the protective urethane layer, a factor in the product’s life once it is on the floor, is referred to in “mils.” Mil ratings vary based on the application of the flooring, with 12 mils or less found in residential products and 20 mils or greater in commercial products. Once these layers are combined, the flooring is stamped with a texture, enhancing the appearance of the wood-grain pattern or other pattern used.

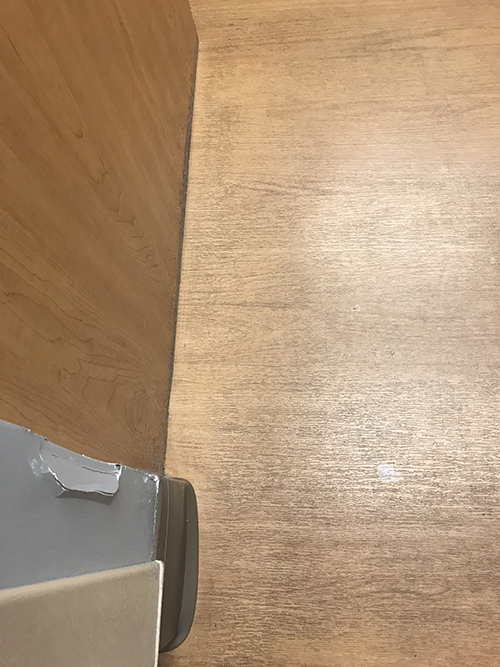

Improper care leads to biofilm buildup on embossed LVT flooring. Image courtesy of Jim Toth Jr.

Commercial facilities are choosing LVT because it has a low environmental impact as well as lower maintenance costs when the manufacturer’s standard of care is followed. The design of the ultraviolet (UV) coating eliminates the need for topically applied protective coatings such as floor finish.

The regular removal and reapplication of floor finish processes are a familiar routine for floor technicians who are trained to maintain a high level of appearance on finished vinyl composition tile (VCT) floors. It is a laborious, strenuous process of burnishing, top-scrubbing, chemically removing, and reapplying the coating on the floor. But what do you do when the floor does not require this type of maintenance?

With the benefits of a new flooring type, come some challenges in how to clean it, especially for technicians who haven’t received training or guidance on the specific characteristics of LVT.

Unlike VCT, the texture of LVT creates a low spot where detergent, soil, and water collect. The high points of this texture act as a squeegee, removing cleaning solution and soil from mops and auto scrubbers, leaving small amounts of detergent, soil, and water in the low spots.

As a result, LVT floors can darken and look dull from the residues left behind—a frustrating scenario for facilities that have invested in flooring they anticipated would save money and look beautiful for years.

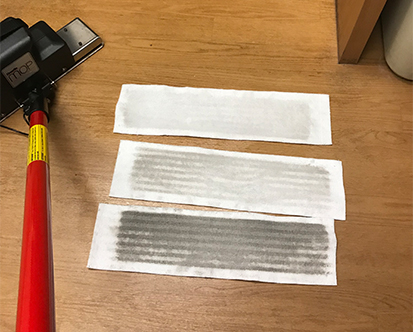

Combined with the mechanical action of an orbital cleaning machine, a microfiber pad has the ability to penetrate deep into the texture and trap and hold soil for removal. This photo shows results from the first cleaning (bottom), second cleaning (middle), and third cleaning (top). This was a corrective cleaning to get the LVT floor back to baseline. Image courtesy of Jim Toth Jr.

New floor, new focus

The texture of LVT floors is often so fine that pads and brushes, a staple for cleaning technicians, cannot get into the embossed pattern to remove the residue.

So how do we evolve our cleaning processes to keep pace with LVT flooring?

One solution is to switch from rotary cleaning machines to orbital equipment with a dense polypropylene pad that cleans deep into the embossed surface. Orbital equipment provides more cleaning action than rotary equipment, and the small, tight orbit of the unit enables it to clean deep into the embossing from many angles. Polypropylene fibers are not abrasive and will not damage the protective coating.

The next question is: How can equipment and processes evolve to maintain a high appearance on LVT so that daily and routine cleaning processes eliminate the need for restorative cleaning?

One effective solution is pairing single-use microfiber pads and orbital machines. The microfiber’s ability to penetrate deep into the texture and trap and hold soil for removal, combined with the mechanical action of an orbital cleaning machine, creates a process that helps maintain the original brilliance of LVT floors. This process uses only water—no detergent—as the residue left behind in previous cleanings contains detergents that are reactivated during cleaning. However, depending on facility type , e.g. hospitals, health care facilities, you may still need to add a detergent or disinfectant to the process.

The use of this cleaning process is growing in the health care sector, especially after months of heavy patient loads that prevented environmental services (EVS) staff from deep-cleaning floors. Health care facilities have found this system reduces cross contamination, eliminates the need to transport and launder microfiber mop heads, and doesn’t require taking patient rooms out of service for deep cleaning.

Unlike auto scrubbers, orbital machines have no exhaust, making their use an ideal final step in cleaning patient rooms.

LVT floors represent a new challenge for cleaning technicians. We cannot expect to meet these new challenges with the same old processes. As flooring evolves, our processes and equipment must evolve with it.