As the world continues to pivot to meet the challenges associated with a global pandemic, cleaning organizations are in desperate need of viable information to respond to the daily rollercoaster ride of change. These changes include training new and existing staff, furloughing employees, reducing staff, adjusting cleaning frequencies, and adding new levels of service, to name a few.

Every segment of the cleaning industry looks different today than it did eight months ago. Published cleaning tasks, tools, and times—as well as training on how that information is used—is in demand now more than ever. For the last five years, a group of industry leaders has volunteered to develop solutions and resources for these challenges that can be used to standardize and benchmark against other organizations’ guidelines.

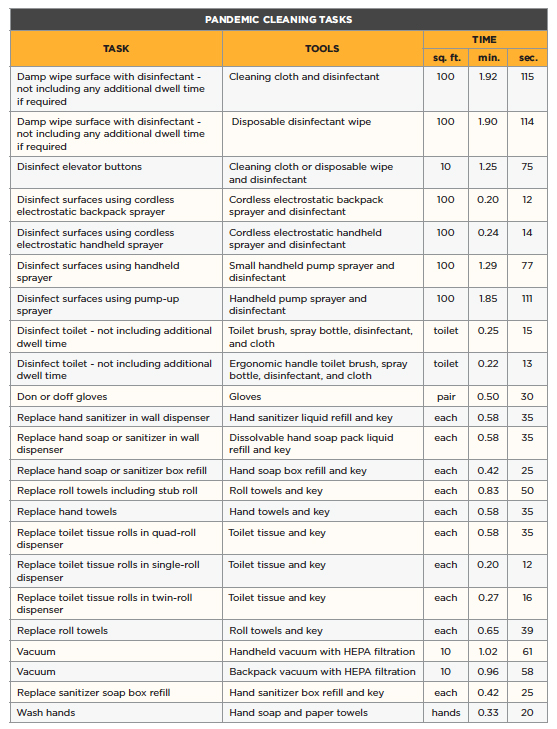

The ISSA CMI Workloading & Benchmarking Council serves as a nonprofit resource to develop education and certifications while quantifying and disseminating ideas and practices for workloading labor. Council members are committed to researching, developing, and standardizing workloading concepts and processes through collaborative benchmarking and innovative practices. Through this work, the council has created an initial list of tasks, tools, and times specific to pandemic-related cleaning to help simplify and increase the speed of workloading and staffing. See the Pandemic Cleaning Tasks chart below.

Calculation guidelines

Workloading is the foundation of a successful process-driven cleaning program. When using this chart above to workload, follow these guidelines for calculating cleaning times:

- Train cleaning workers to perform the workloaded tasks with the prescribed tools.

- Have cleaning workers physically demonstrate the ability to perform the workloading using actual supplies.

- Define cleaning processes and include flow-charted solutions.

- Validate production rates for flow-charted cleaning processes. Include an explanation and justification for any deviations from validated production rates.

- Conduct a formal change review for any adjustment to a flow-charted cleaning process.

- Equally apply workloaded production rates for a defined cleaning process.

- Train employees on all tools and equipment used to achieve the desired production rate.

- Regularly evaluate cleaning workers’ ability to meet the workloaded cleaning times.

- Make available all required cleaning tools, chemicals, and equipment to complete tasks.

- Include a feedback and improvement process for workloaded buildings.

- Track where the dirt goes using equipment filter logs, solution changes, and chemical consumption.

- Account for factors that affect productivity including soil types, travel time, weather, logistics, types of flooring, soil buildup, security, and other non-cleaning-related impediments.

Cleaning is essential to protecting public health. Whether cleaning plans are executed in-house or by service providers, they require integrated and transparent resources. Use every resource at your disposal to ensure you can be proud of the choices you have made when the outcomes of the pandemic are viewed in the rear view mirror. All organizations have the same objective—to get the most effective cleaning output with the resources allocated. The ISSA CMI Workloading & Benchmarking Council continues to provide the necessary resources to guide organizations toward this objective.

To receive more information or participate in future committee work, contact the council at [email protected].