The green cleaning movement is embracing innovative solutions that will minimize the environmental and health impacts of cleaning while enhancing its efficiency. These innovations will use various technical platforms and new materials to enhance training, cleaning, and product packaging.

Training with augmented reality

Augmented reality (AR) technology overlays digital information onto the physical world, providing interactive and immersive training experiences. Through AR, new employees receive hands-on instruction without a trainer’s constant presence. AR guides users step-by-step through cleaning procedures, highlighting correct techniques and common mistakes. This technology simulates various scenarios, such as spill clean-ups or hazardous material handling, enabling staff to prepare for real-life situations.

AR can be continuously updated with new procedures and safety guidelines, ensuring that employees always have access to the latest information. It allows for remote training, reducing carbon emissions associated with travel.

Green cleaning with robotics

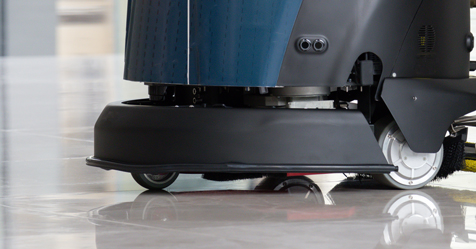

Robotics are transforming the cleaning industry by automating repetitive and labor-intensive tasks. Robotic cleaners, such as autonomous vacuums and floor scrubbers, are already utilized

in various settings, including manufacturing sites, warehouses, airports, and other buildings with large open spaces. These robots operate with high precision and consistency, ensuring thorough

cleaning while freeing employees for more complex tasks.

Robotic cleaners equipped with sensors and artificial intelligence (AI) navigate complex environments and avoid obstacles. They can adjust their cleaning methods to different surfaces. Future innovations will include robots with arms capable of performing multiple cleaning tasks.

Cleaning crews looking to optimize their resources and reduce waste can program robotic cleaners to use a specific amount of cleaning solution and water. The equipment’s ability to operate on demand and during off-peak hours can lead to energy savings.

Demand-based cleaning with sensors

In a smart building, sensors using Internet of Things (IoT) technology can detect high-traffic areas and trigger cleaning robots to address those spots frequently. Air quality sensors can alert the

system when particulate levels exceed a certain threshold, prompting immediate cleaning actions.

This approach paves the way for demand-based cleaning, in which cleaning activities are triggered by real-time data rather than fixed schedules. Demand-based cleaning reduces resource consumption by avoiding unnecessary cleaning activities, ensuring that cleaning solutions and water are used only when required.

IoT-enabled systems inform cleaning crews when restroom dispensers need refilling, creating a better restroom user experience. The systems also signal when preventive maintenance is needed, alerting facility managers to potential issues before they become problems and extending the lifespan of cleaning equipment.

Film pouches replace rigid plastic

Cleaning products have traditionally come in rigid plastic bottles, leading to high material usage and transportation inefficiencies. Multi-layer film pouches present a promising alternative. These

flexible pouches require significantly less material to manufacture. Their lightweight nature leads to lower transportation costs and reduced carbon emissions.

Multi-layer film pouches have built-in barriers that protect against moisture and oxygen. Constructed of biodegradable and compostable films, they offer eco-friendly disposal options. Refill systems using these pouches encourage consumers to reuse rigid containers, further reducing waste.

This innovative shift in packaging not only minimizes environmental impact, but also appeals to eco-conscious consumers. Future innovations will eliminate packaging altogether through the production of cleaning chemicals on-site.