There are many choices available when it comes to selecting industrial floor care equipment. Between autoscrubbers, scrubber-driers, battery-powered sweepers, and burnishers, the market for hard floor and carpet cleaning equipment is advancing because of new technologies that make the equipment more efficient and improve business operating costs.

One area in the industrial cleaning industry where we see modernization is battery design and charging systems. While the majority of industrial electric machines and floor care vehicles use traditional lead acid batteries, original equipment manufacturers (OEMs) are increasingly switching to modern lithium-ion batteries. In fact, analysts forecast the global lithium-ion market will reach US$77 billion by 2024.

Applications for Lithium-Ion

Different applications have different requirements, so the value proposition for lithium-ion varies across a range of uses, from consumer electronics to electric vehicles to commercial and industrial equipment.

For example, power sport vehicles such as electric motorcycles and scooters need to be lightweight in design with a battery that enables high power and a long range—requirements that lithium batteries easily satisfy. On the other hand, industrial floor care machines, which are denser, have typically relied on larger lead acid batteries that can provide durability and power at a lower cost.

As education around battery alternatives spreads, the emergence of lithium-ion batteries in the industrial cleaning industry is increasing. It is important for OEMs to understand their applications’ unique needs and assess whether their equipment designs require updating.

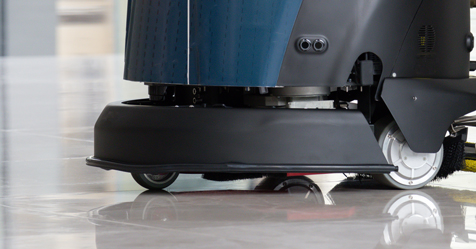

Floor Care Application

A main reason OEMs of industrial floor care machines are switching from lead acid to lithium-ion batteries is to enable higher productivity. Lithium batteries deliver longer run times, charge in a fraction of the time required by traditional lead acid batteries, and do not require maintenance—that adds up to dramatically higher equipment availability.

Pros and Cons

Like most technologies, lithium-ion batteries have drawbacks. The upfront costs for lithium-ion batteries can be daunting, even if the total cost of ownership is lower over time. Fortunately, the cost of lithium-ion battery packs continues to come down at a predictable rate, due to manufacturing economies of scale and incremental technology improvements.

Additionally, below are three ways integrating lithium-ion charging solutions can help building service contractors and in-house facility managers achieve their desired returns on investment:

No. 1: Minimizing Replacement Costs

Lithium-ion batteries typically have a useful life exceeding five years. A well-designed lithium-ion battery pack can last as long as the equipment it powers. This eliminates the need for costly battery replacements and maintenance, significantly reducing total cost of ownership.

No. 2: Size Benefits

Lithium-ion batteries can be up to four times lighter and three times smaller than lead acid batteries. That means a lithium pack with the same footprint can offer significantly longer run time. Alternatively, designing a machine around a smaller lithium pack can allow more space for cleaning fluids, or enable smaller, more ergonomic machine form factors.

No. 3: Lower Energy Costs

Not only does lithium-ion charge faster than lead acid, it also requires significantly less energy. That means a reduced environmental impact and carbon footprint. Imagine saving 10 to 15 percent on the electricity to power your equipment; this adds up to significant savings throughout the life of the equipment.

Another challenge is that lithium-ion cells can be thermally volatile if mistreated or used outside of their safe operating areas. However, these risks are preventable through standard safeguards and safety margins.

Lithium-ion battery packs should be properly integrated with a battery management system and charger that communicate together to enforce and follow the proper safety recommendations. OEMs that understand the potential risks and follow best practices will be able to maximize the benefits that lithium-ion solutions can provide to end users of industrial floor care machines.