When Dr. Gavin Macgregor-Skinner travels, he more closely resembles an astronaut preparing for a space journey than a traditional traveler on a business trip.

He knows the dangers of potentially dangerous infectious agents. He knows the proven dangers of infectious agents such as the coronavirus. He knows that there could be something new right around the corner that poses a danger to human health. He doesn’t take any chances.

Dr. Macgregor-Skinner is an epidemiologist who concentrates his efforts on the global cleaning industry. He is now the director of the Global Biorisk Advisory CouncilTM (GBAC), a division of ISSA.

Some of the activities and actions of others he sees surprise him. He recalled a recent trip through a TSA checkpoint at a major airport during a shift change for agents.

“I kid you not. I saw one agent take off his face shield and hand it to his replacement. No cleaning, no disinfecting, nothing,” Dr. Macgregor-Skinner said.

There is a huge disconnect, between what people know they should do and what they actually do.

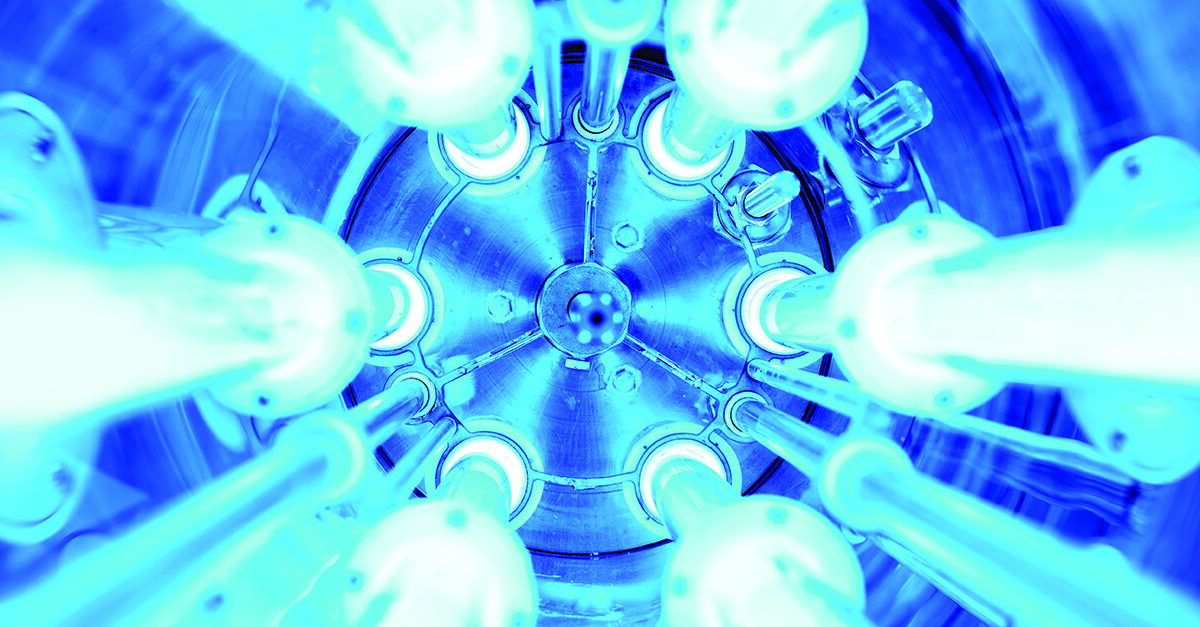

One way to solve this issue is to put antimicrobial protocols in place that really work and don’t always require a human to implement. An example is ultraviolet-C (UV-C) technology.

“UV-C light (after cleaning) has significantly mitigated infection risks with environmentally mediated transmission routes,” Dr. Macgregor-Skinner said, for bacteria “such as Clostridium difficile (C. diff) and vancomycin-resistant Enterococci (VRE). And just like traditional, chemical disinfectants, UV-C light has a required contact time.”

Some UV-C units are portable and can be targeted to specific surfaces. Other systems provide antimicrobial light much like a traditional lightbulb in a room.

Manufacturers of UV-C technology, in addition to industry consultants, can point to data that prove it works and is an effective antimicrobial innovation.

Why consider UV-C?

Camila Salazar, an account consultant with Nichols Distribution in Indianapolis, helps her clients find solutions that include innovative disinfection technologies. She works closely with Pure Protective Equipment, which is made up of a family of companies, including UVC Lightforce, UV Angel, and Lucid Drone Technologies, and led by Bill Fisher, president of Pacific Floorcare.

“I help fast-track my customers to productivity and process improvement gains by using UV-C as their antimicrobial tool to quickly eradicate and destroy the cellular growth of microorganisms,” Salazar said. “Clinical studies prove customers adding UV-C light to standard regimens reduces bacteria contaminant counts by 88% in comparison to just 63% with traditional methods. That is a huge savings for health care and commercial institutions. It’s another arrow in their quiver to supplement their current standard operating procedures and protect their communities. As a result, transmission of infection decreases exponentially, allowing for peace of mind during volatile times.”

The scientific community has long understood the innovative power of UV-C light, according to Grant Morgan, the CEO and founder of R-Zero Systems, a company that manufactures UV-C equipment. “UV-C has long been the gold standard for infection prevention in hospitals, and UV-C has been used in countless other air, water, and surface applications for over a century,” he said. “UV-C was key to fighting early public health crises, like measles and tuberculosis.”

Timothy Sulecki, the president of MaxAssure Inc., a manufacturer of ultraviolet equipment, said UV-C is a long-proven method for disinfecting air, water, and nonporous surfaces. “Multiple lengthy case studies prove both the efficacy and economic benefits of UV-C as part of a disinfection process,” Sulecki said. “For decades, UV-C has been an important tool to health care facilities around the globe, providing a demonstrated, easy-to-use method of disinfection.”

UV-C offers next-level protection in coordination with regular cleaning and disinfecting protocols, according to Mike Colligan, the director of corporate sales with Pure Protective Equipment. “The use of UV-C is a chemical-free process that does not leave behind any residue and allows for immediate occupancy of the space,” he said. “In addition, other methods of disinfection introduce the element of human error into the cleaning process. The use of UV-C is another layer of disinfection for the facility to ensure proper cleaning procedures and protocols are in place.”

How it works

“UV-C or ultraviolet light in the 200 to 280 nanometers (nm) range has shown to be effective against pathogens under specific conditions,” according to Dr. Stefan Wagener, a scientific advisor for GBAC. “The effectiveness depends on the specific wavelength used, medium to be treated, the amount of UV energy released, the distance between the UV source and the material being exposed, and, very importantly, the conditions in which pathogens are in.”

The UV-C process is called ultraviolet germicidal irradiation (UVGI), explains Frederick Schetrompf, the vice president of MaxAssure Inc. “This disinfection method uses short-wavelength UV-C (~254 nm) to kill or inactivate microorganisms by disrupting their D-/RNA (apoptosis), leaving them unable to perform vital cellular functions such as replication. The result is cell death.”

So, it’s not as simple as turning on an ultraviolet light and zapping into oblivion what can hurt you.

“To be safely and effectively used, UV-C light must come in direct sight with the treated air or surface, as areas shadowed from the light will not be treated,” said Mike Hartmann, the executive vice president of The PYURE Company, which manufactures equipment using ultraviolet light that creates hydroxyls and organic oxidants. “UV-C cannot be directly exposed to humans as it is proven harmful to skin and eyes, and prolonged and repeated use will damage materials in a treated room.”

Applications for use

Dr. Linda Lee is the chief medical affairs and science officer with UV Angel, a manufacturer of UV-C technology. She has spent more than 30 years working with a wide range of organizations to eliminate disease and create safer indoor environments. “UV-C is a well-studied, well-understood technology that has been around for years and used to treat environments and reduce pathogens,” said Lee. “There are hundreds of uses and everyday applications for UV-C treatment in the air, on surfaces, and in water. Applied correctly, it can be safe for use with many modalities.”

UV-C towers are commonly seen in hospitals. “These are rolled into the room, people leave the room, and it is sealed off from anyone entering the space while the tower is emitting UV-C energy in the room,” said Dr. Lee.

In addition, UV-C is used with building ventilation systems. “There are a number of ways to incorporate UV-C into HVAC systems,” according to Morgan. “The most common application is inserting UV-C lamps into the ducts of an HVAC system to disinfect air as it passes over the lamps before entering a room. It can also be used near the filtration system, which not only disinfects the air, but also disinfects the filters that catch, but don’t inactivate, harmful pathogens.”

According to Morgan, exposure times vary greatly and are impacted by several variables such as airflow rate, humidity, the types of pathogens being eradicated, the intensity of the light, the size of the radiation chamber, and more. Given how complex modeling can be and how much is at stake, it’s advisable to consult an expert to understand how much exposure time is needed for your application.

UV-C light can be used for antimicrobial purposes if enough UV light (dose) reaches the pathogens, explained Dr. Wagener. “They need to be exposed to the light for a long enough time, and nothing shades the pathogens from the light. For that reason, UV-C light can be used in HVAC systems where air passes in front of the light for a long enough time, and the same is true for in-water applications if the water is clean.”

Any user of UV needs to assess the intended application and usefulness carefully, Dr. Wagener stressed. “UV systems designed and specifically customized for installation in a specific air-handling system (HVAC) to treat the air while it is passing through, will likely be much more effective per unit dose of UV than UV lights placed in a room full of equipment, furniture, and other objects that provide shade,” he said.

Routine maintenance is also important. “Over time, UV-C light bulbs will reduce the output of UV-C light, and any time the bulb gets dirty, it will be less effective,” Dr. Wagener said. “For that reason, shields and/or filters are sometimes used in front of bulbs in an HVAC or water system to keep the bulbs clean. As long as the UV-C bulbs are in a closed system (no UV-C light gets to the outside), they are considered safe.”

Safety concerns

Overall, manufacturers of UV-C equipment see an acceptance of this type of technology. “Our observations show us that the demand for UV-C as a disinfecting tool has increased over the last year due to the global pandemic and is safe to use as directed in unoccupied spaces where there is no exposure to people and porous materials,” Hartmann said.

Obviously, safety starts with training. “As with all systems designed for health and safety, training and support are critical,” Salazar explained. “We have developed customized training and implementation programs based on industry segment. Knowledge is power. The more comfortable and educated on a system you are, the more likely it is accepted.”

Eight years ago, MaxAssure embarked on educating and gaining acceptance in the UV industry. “Although UV-C is a highly safe and effective means for disinfection, it was then and remains now difficult to convert some folks from more ‘traditional’ disinfection processes,” explained Sulecki. “While UV-C has its own inherent risks, safety measures have been built into our devices.”

“UV light and especially UV-C is high-energy radiation and a significant human and animal hazard,” said Dr. Wagener. This being said, using UV-C in an occupational setting requires that no skin and/or eye contact occurs at any time. “For that reason, UV-C application is either in a closed system or without any occupancy during the application. In addition, any surface application requires the surface to be clean and unobstructed. Trying to use it on dirty, soiled surfaces will not work well.”

“When operated correctly, this technology is safe,” Morgan added. “Humans and animals should not be in the room while a UV-C device is running since the light can be damaging to eyes and skin. It’s imperative that UV-C devices come with built-in safety features, such as a motion detector that shuts down the device if there’s movement in the room, as well as detailed manufacturer instructions for safe operation. Training programs for those who operate the devices are also important.”

Some innovative systems are developed to be used in occupied spaces, however. As Lee explained, she works with safe and shielded technology that “is safe for occupied spaces because of the shielded UV-C and continuous treatment.”

Salazar pointed to advancements in ceiling-mounted units in an enclosed UV-C chamber that continuously operate at the source of the pathogens (humans) with patrons, patients, and humans in the area. “They are safe to use in the presence of humans, who shed 37 million types of pathogens per hour!” Salazar said.

Colligan said with the current pandemic operators are looking for a next-level solution in addition to the current cleaning and disinfecting methods. “While there is no one perfect way to clean and disinfect, the use of these layers of cleaning protocol allows for a cleaner, safer workplace, school, or environment,” he said.

Automation and robotics

Automation is the obvious path to the future, according to Schetrompf. Ensuring there is effective overlap between the level of automation employed and safety is paramount. “In the last 18 months, we have observed big leaps made in the bridge between automation and safety using next-generation sensors and computer modeling. It is exciting, to say the least,” Schetrompf said.

Colligan believes that the use of robotics in the industry continues to evolve. “Regardless of the application, robotic, human, or otherwise, the intensity of the UV-C lamp will still define the time necessary to effectively kill or inactivate the pathogen and drive the productivity time,” he said.

The future

The pandemic has led to rapid growth in the UV-C market, and Morgan believes the industry will only see this growth continue in the new normal—especially as bodies such as the National Institute of Standards and Technology (NIST) and the International Ultraviolet Association (IUVA) develop uniform performance standards.

“It is our belief that the coronavirus pandemic will ultimately have a larger impact on infectious disease protocols—along with every other aspect of modern culture—than any other event in history,” Morgan said. “From this point forward, businesses around the globe will be putting infection prevention and environmental safety at the forefront of their day-to-day operations, making technologies like UV-C a part of standard disinfection protocols. While today the focus is COVID-19, tomorrow it will be norovirus, the seasonal flu, E. coli, the common cold, and every other virus, bacteria, fungi, or mold that threatens the human immune system.”

“The seasonal flu alone impacts 40 million Americans every year,” Morgan said, which costs the United States economy more than $10 billion annually—and “somehow as a society we’ve come to accept that as normal. I believe UV-C will play a huge role in decreasing those numbers and ultimately setting a new standard for infection prevention in our post-pandemic world.”

While the global pandemic presented an obvious, immediate increase in UV-C usage, there is an anticipated, heightened awareness remaining. According to Sulecki, “Demand for better disinfection management of our environment, particularly public spaces, is likely here to stay. Once largely limited to health care and water treatment applications, the future poses limitless applications so long as the driving force of design includes safety.”

Salazar added, “The use of UV-C technology in our everyday lives is here to stay, as is the hyper-focus on cleaning and disinfection procedures. Even though we are seeing the economy start to reopen and are expecting herd immunity by early summer, growing trends from customers are their increased focus on implementing proactive prevention strategies and instilling confidence in their patrons that they can return to a safer environment. Many were doing just enough to ‘get by,’ but what can they be doing now to protect their tenants, patients, employees, students, and others?”

If there’s anything certain about the current pandemic, it’s that the landscape is constantly changing, the behavior of the virus is difficult to predict, and SARS-CoV-2 will not be the last dangerous pathogen to challenge the world, said Kathryn Kulick, the chief product marketing and financial officer of Neon LLC, a company that provides several UV-C solutions. “Clearly, the best approach for addressing the unknown is to begin with proven approaches and straightforward safety procedures,” she said.

With these thoughts in mind, we must all now take the time to examine our cleaning, disinfecting, and sanitizing strategies. Are we just doing enough to “get by,” or are we doing all we can to safeguard those in our buildings, our customers, employees, and ourselves?