As a business, we try to supply our toolbox with the latest in technology and equipment so that we can not only better serve the customer, but also serve the customer in a profitable way. Success depends on our knowledge of the technology and equipment we use. But do we have the proper knowledge of the standard for our industry? The IICRC S500 Standard and Reference Guide for Professional Water Damage Restoration, which we will simply reference as the “S500” moving forward in this article, is the tool that can complete your toolbox and help your business successfully complete jobs involving water losses.

In this article, we will highlight key elements provided by the S500 and how you can utilize them in your business.

Use the latest edition

The fourth edition of the S500 came out in December 2015. Many in the industry are still using the third edition and not recognizing the changes that were made in the current edition. This prevents your company from completing jobs and getting paid for those jobs. So, the first thing you need to do is make sure your business is using the fourth edition.

The fourth edition is a great resource to help your business understand how to successfully mitigate a water loss job. The standard is in the front of the document, followed by the reference guide. If you are in section 10 of the standard, you can go to chapter 10 of the reference guide to get a more in-depth explanation of the information in the standard. Sections and chapters are directly related to each other, creating an easier document to explore.

Familiarize yourself with key terms

Before you start using the S500 as a tool, you must know a couple of key definitions to understand the level of importance of the text.

If you see the words shall or should in a sentence, they are components of the standard of care. Shall is used for text that is mandatory due to natural law or regulatory requirements. Should is used for text that is accepted standard of care to be followed, but not mandatory by regulatory requirements.

Other keywords include recommended, which is advised or suggested, and may or can, which denote permissive or possible action. Each of these terms aids your business in determining the level of importance of items in the standard as well as the water loss and procedures you will follow.

Safety and health come first

The IICRC places safety and health at the top of the list for all losses. Restorers need to provide for the safety and good health of their workers as well as the occupants of the structure they are restoring. This includes applying proper engineering and administrative controls as well as personal protective equipment (PPE).

Documentation is crucial

Once the environment is safe, documentation provides a safety net for your business to not only provide support for your invoice, but also to lessen your liability.

Today our industry has embraced technology using touch-screen tablets or computers for electronic platforms to gather our data. Use these devices to make sure you have the authorization to repair, authorization to pay, and a statement of satisfaction. On the drying side, you should have a record of drying conditions and moisture points, which includes atmospherics, moisture points and dry standards, equipment numbers and placement, and other supporting documentation. Notes on each loss are a must.

Categories by numbers

The category of water loss is determined by the level of contamination at the beginning of the loss. There are three categories:

- Category 1: Originates from a sanitary source and does not pose a substantial risk from dermal, ingestion, or inhalation exposure

- Category 2: Contains significant contamination and can contain potentially unsafe levels of microorganisms or nutrients for microorganisms

- Category 3: Signifies gross contamination and may contain pathogenic (disease-causing) organisms.

It is important to document the reasons you are choosing the category for each loss. The S500 gives you detailed definitions and examples for each of the three categories. Don’t cut and paste the document’s information to your notes, but paint the picture for each loss (sight, smell, etc.).

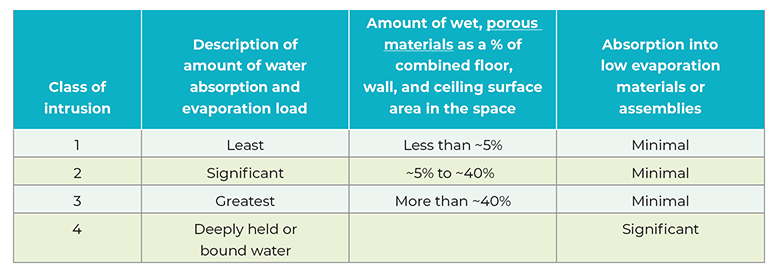

Class of intrusion

The class of intrusion is the amount of water absorption and evaporation load. It is determined by the amount of wet material as a percentage of the combined floor, wall, and ceiling surface area. It is important to know that the class is determined after demolition or remediation activities are completed. Remember to provide humidity control during these activities until the class can be determined and the proper equipment levels are set. The chart on the previous page provides information on each class of water intrusion.

Set drying goals

Our main goal during the drying process is to dry the wet materials. To do so, a dry standard or drying goal needs to be established for each material type. Take the dry standard from a reading on an unaffected material in the property being dried. Do not use a canned list of dry standards as they can produce inaccurate results.

The science of drying can be confusing. The S500 provides basic background information on the terminology and science of restorative drying. This information is important to understand so your business can effectively and efficiently remove moisture from materials and the environment.

Air filtration factors

Air filtration devices give us the opportunity to HEPA filter the air when the need arises. The standard outlines their use, especially on jobs that are contaminated (category 3 water), when particulates are being added to the air (drawing moist air out of potentially contaminated cavities using negative air pressure or during demolition even if contained), and if health concerns are present with the customer. If you are working with an insurance company, you will want to get preapprovals.

Are antimicrobials needed?

You’ll use antimicrobials for most water losses. However, this is not the case on a category 1 loss, as stated in the standard. If a loss is a category 1, that means the water is not contaminated and would not require an antimicrobial. Antimicrobials work best if the surface is cleaned first and when the label directions are always followed, with no exceptions.

HVAC system complications

HVAC systems can complicate water loss jobs. In projects where category 2 or 3 water has entered directly into the HVAC system, you must contain, disassemble, and remove the system components. The components should then be cleaned by a qualified HVAC contractor.

Add the equipment

We all value the equipment we use, because it is an important component of not only better drying performance, but also of profitability. The S500 provides a simple and detailed calculation for dehumidifiers and the air mover calculation. These calculations provide the proper amount of equipment to most efficiently dry a structure. They also provide a justification for the equipment you have placed.

Use the S500 to complete a water loss job

The S500 (fourth edition) provides background information and a roadmap of how to successfully complete a water loss job. This is the first item you should add to your toolbox to ensure you are following industry standards. By following the S500, you can make all your water losses a success.

To purchase the S500 or other standards, go to webstore.iicrc.org. Standards can be purchased in paper form or in a digital format that gives you access to all standards in an economical annual subscription. A prerecorded webinar of this article is available to IICRC-Certified firms in the Certified Firm Toolbox at iicrc.org.